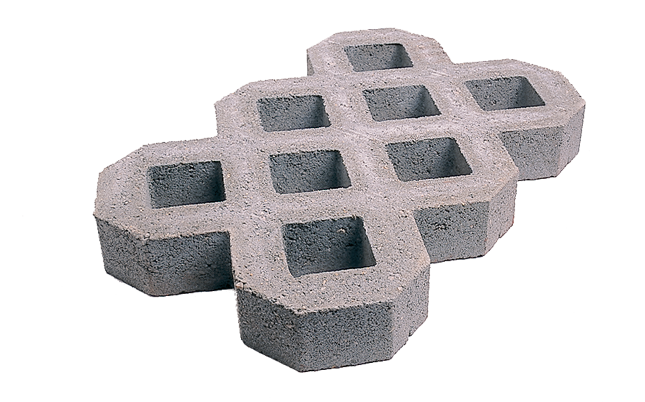

Percstone

Note: All Products Sheets are supplied in Adobe PDF format.

Download Product Sheet

- 1. Excavate subgrade material to the depth required for particular application and compact the soil

subgrade to at least 95% of modified Proctor Density. The base for Percstone is typically compacted

¾” modified stone. The thickness of the base depends on the load and the strength of the soil subbase

as directed by site engineer, architect, or landscape architect. (For example, a typical fire lane or

parking lot would require 8”-12” of stone.)

- 2. Install edge restraint using concrete curb or concrete toe.

- 3. The setting bed should be concrete sand conforming to ASTM C 33. Thickness of the sand should

be 1”. The sand should be properly screeded to proper elevation allowing 3-1/8” for the Percstone

units. The screeded sand should not be saturated nor disturbed.

- 4. Install Percstone units on bedding course in pattern desired allowing approximately 1/8” between

units.

- 5. Where required, cut Percstone units with an approved cutter to fit accurately, neatly and without

damaged edges.

- 6. Tamp Percstone units with mechanical vibrator uniformly level, true to grade and free of movement.

- Embankments: Percstone units are placed directly on graded and compacted soil, working from the

bottom to the top of the embankment. The recommended maximum angle is 70 degrees; for slopes

over 45 degrees, Percstone units should be staked every third row to secure them until vegetation is

established.

- Streambanks and Lakesides: The maximum recommended slope for this application is 45 degrees.

Frequently, a base of gravel (minimum 4”) and a layer of filter fabric are necessary to prevent scour

from moving water. In areas where vegetation will not grow, gravel should be placed in the voids of

the Percstone units.

- For further information, refer to ICPI Tech Spec. #8, a copy of which will be provided upon

request.